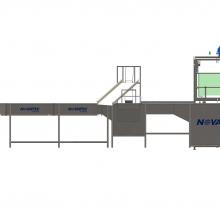

Water Bins Tipper WBD_200

Our Water Bins Tipper receives bins and unloads them in water. It is automated to suit your needs.

Technical Description

The machine is a water unloading system for apples, in boxes or bins. It is a discontinuous fully automated unloading system with a three (3) station process. It is an ideal system for small and medium projects.

Technical Features:

- Metal structure which has been properly welded and treated in stainless steel AISI 304

- Full Bins Station: The forklift place the full BINS in the First Station and the operator presses the start button in order the cycle to begin

- Motorized Pusher to move the full Bin in the Immersion Position, second station

- Immersion Position: The full Bins stop in Second Station, where they submerge inside the water tank, uploading the apples in the water

- Motorized Lifting / Submerging Platform for the gentle unloading of the apples inside the water tank

- Empty Bins Accumulating Position: The empty Bins arrive in the Third Position through the Lifting / Submerging Platform and an idle roller conveyor

- Stainless Steel AISI 304 Water Tank for Bins unloading and apples floating

- Stainless steel AISI 304 buffering channel for feeding the roller inspection table

- Specially designed supports, in stainless steel AISI 304, for leading the product in the infeed of the Roller Elevator

- Rotating brush for smooth feeding of Roller Elevator

- Filtering system for leaves and foreign objects collection

- Floating device for automatic water feeding and level adjusting

- Motorised pump for water recirculation through water tanks and buffering water channels

- Series of PVC pipelines and related valves

- Capacity: Up to 25 Bins / Hour (This Water Unloading System is ideal for one lane & two lane Electronic Sizers)