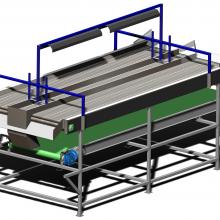

Roller Inspection Table

Novatec’s Roller Inspection Table helps the workers to manually inspect the products. Various models are available.

Technical Description

The Roller Inspection Table helps the workers to manually inspect the products. The speed of the machine can be easily adjusted, based on the flow of the products. The rollers of the inspection table rotate, thus rotating also the products, and making the inspection easier. Two drop-out set of rollers are designed in order to throw away the soil that is trapped between the rollers. On the middle, a separator is placed. This facilitates in dividing the inspection table in two main inspecting areas, where it is easier for the workers to reach the products. Also, it creates a small gap where the workers will place the second quality products and guide them outside the inspection table, to be stored in bins.

Technical Features:

- The metal structure has been properly welded and treated with three layers of polyurethane varnish

- Specially designed infeed hopper

- Series of galvanized or aluminium metal rollers (Optional: PVC Rollers or soft cover Rollers, depending of your product)

- Two (2) set of endless, galvanized side chains

- Rollers rotation system with special gear end cups

- Properly designed middle partition bars for the disposal of waste products

- Motorized conveyor belt (food grade, PVC belt) on the bottom of the Inspection Table, which leads the products out of the line, placed vertically to the Roller Inspection Table and under the rollers

- Main drive by means of proper gear motor (Waste Belt)

- Top lighting system

- Two (2) platforms with stairs for the workers

- Main drive by means of proper gear motor and electronic speed variation (Inverter)