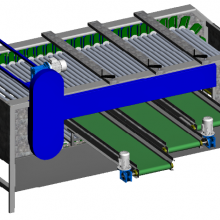

Lift Roller Grader

Our updated Lift Roller Grader provides more accurate sizing, is easier to operate and has improved access for maintenance and cleaning.

Technical Description

The Lift Roller Grader is the most common type of mechanical sizer for grading vegetables, such as potatoes, carrots, onions, etc. The product is separated by size, gently and accurately. The vegetables travel along the rotating rollers.

Technical Features:

- The metal structure has been properly welded and treated with three layers of polyurethane varnish

- Set of aluminium rollers

- Two (2) set of heavy loads endless chains (one on each side)

- Two (2) series of ramps, on both sides, where the rollers travel on

- Rollers rotation system, for the rotation of all the rollers to same direction

- Specially designed system for lifting the middle rollers «Lift Roller System» and accurate vegetable sizing

- Ergonomic size adjustment handles, located along one side of the Lift Roller Sizer, for the easy grade adjustments during operation

- Specially designed system for properly rotating both roller of each couple

- Main drive by means of proper gear motor and electronic speed variation (Inverter)

- Set of food grade PVC conveyor belts suitable for the exit of the calibrated products

- Reversible cross conveyors / Line Flexibility: sized produce can exit either side

- Set of main drive by means of proper gear motor (for the exit belts)

- Durable, robust and low maintenance design

- Heavy-Duty drive systems for the rollers and the exit belts, built for strength and durability

- Gentle Handling: Low drops guarantees the best possible handling of your products

- Easy Operation: Easy grade adjustments can be made during operation.

- Versatility:Suitable for various vegetables like potatoes, onions, carrots, radishes etc.

- Accuracy: Accurate diameter sizing

- Variable speed control: Electronic Adjustment of roller speed to meet product type, condition and required capacity

- Optional: Infeed Conveyor Belt in order to minimize products fall and evenly distributing the vegetables across the width of the machine to optimize capacity.

|

Model |

Max Capacity |

Electric Power |

|

LR 3/120 |

10 Ton/Hour |

2 Kw |

|

LR 3/150 |

15 Ton/Hour |

2,5 Kw |

|

LR 3/180 |

25 Ton/Hour |

3 Kw |